Advanced Thermal Interface Materials (TIM)

The past few decades have seen an escalation of power densities in electronic devices, power electronics and next generation vehicle electronics. Together with the continuing trend of reduction in device dimensions this has led to dramatic increase in thermal issues within electronic circuits.

Thermal management is therefore becoming increasingly more critical and fundamental to ensuring that electronic devices operate within their specification.

The marketplace offers many material solutions to dissipate heat generated in circuit boards. The challenge is to find the best-suited thermal interface materials with favorable physical and thermal properties to help efficiently run vehicle electronics; as they must also be able to withstand thermal shock, physical vibration and challenging environmental conditions.

Choosing the right Thermal Interface Materials is crucial for the device efficiency, performance and reliability. Instead of sophisticated cooling technique, it is often better to invest in the interface material.

The most appropriate choice of thermal interface material has been shown to:

- Reduce total cost of ownership

- Optimize your thermal management system for performance and price

- Increase reliability and operational lifetime

Anticipating this trend, Momentive has a key focus on developing products with enhanced thermal management properties.

Purpose of Thermal Interface Materials (TIM)

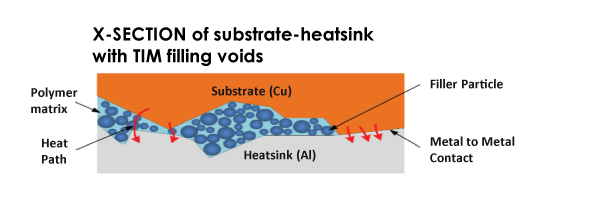

Heat generated by high power semiconductors has to flow through a number of different material layers and interfaces before it reaches the heatsink or coolant. Thermal interface materials displace air gaps to enhance the thermal contact between layers.

The performance of the interface is determined by the thermal resistance (Rth) between the junction and heatsink. Thermal Resistance is influenced by 3 factors:

- Thermal conductivity (λ) - A measure of a material’s ability to conduct heat as measured in Watts per meter-Kelvin (W/mK).

- Bond Line Thickness - A lower BLT will decrease the thermal resistance and ultimately improve thermal performance.

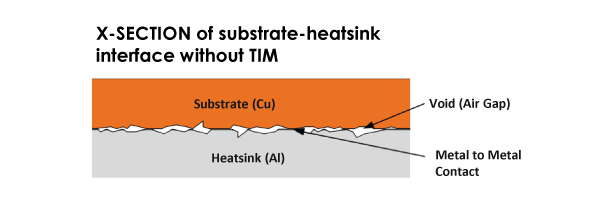

- Contact Resistance - Due to surface roughness and manufacturing processes, the substrate and heatsink can have many microscopic voids in the contact area with adjacent materials. These voids are air gaps which have very poor thermal conductivity (λ Air ≈ 0.03W/mK). To minimize microscopic air gaps, thermal interface materials decrease contact resistance and help conduct heat away from the substrate.

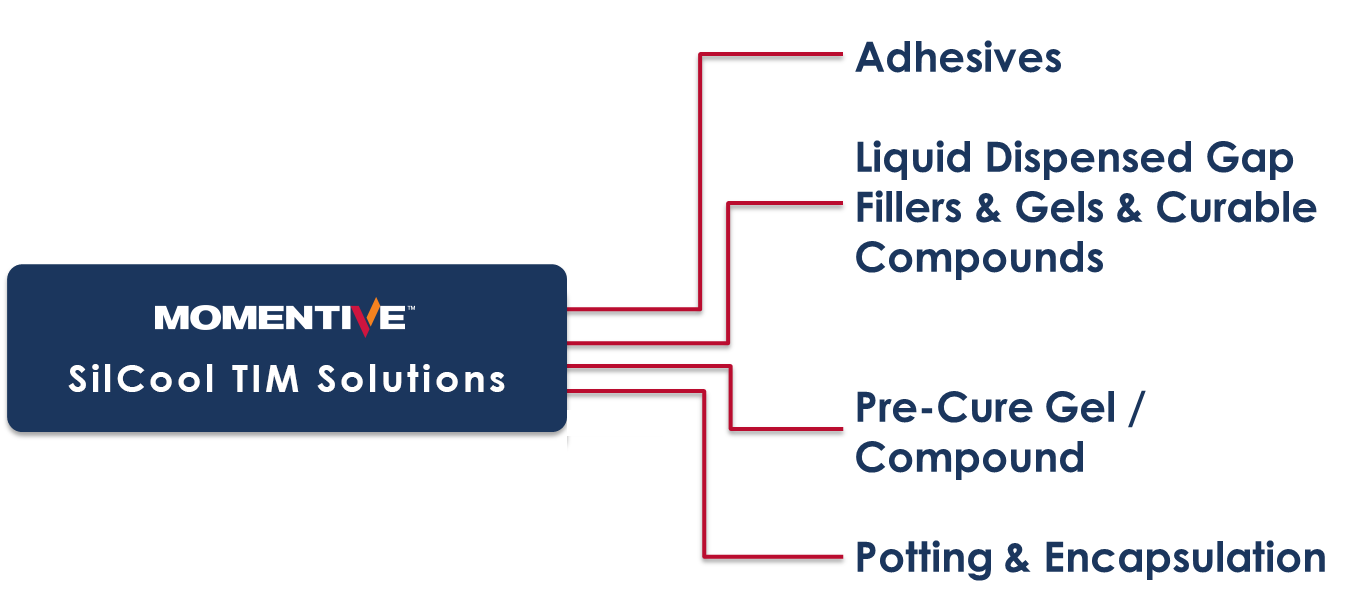

Momentive has a broad portfolio of thermal interface management solutions