Material Solutions for E-mobility & Electrification

As a new era of e-mobility emerges, it's accompanied by new manufacturing challenges that require new material solutions. Companies must innovate in order to meet these challenges. Momentive’s advanced material solutions play an essential role in the vehicles of today and tomorrow. From thermal management and battery solutions to cable and connector materials; from sensor coatings to adhesives and seals -- Momentive’s innovative silicones help shape the future of e-mobility and drive our new vehicles forward.

E-mobility Applications

- 1 Power Electronics

- 2 High Voltage Battery Systems

- 3 Electrified Powertrain

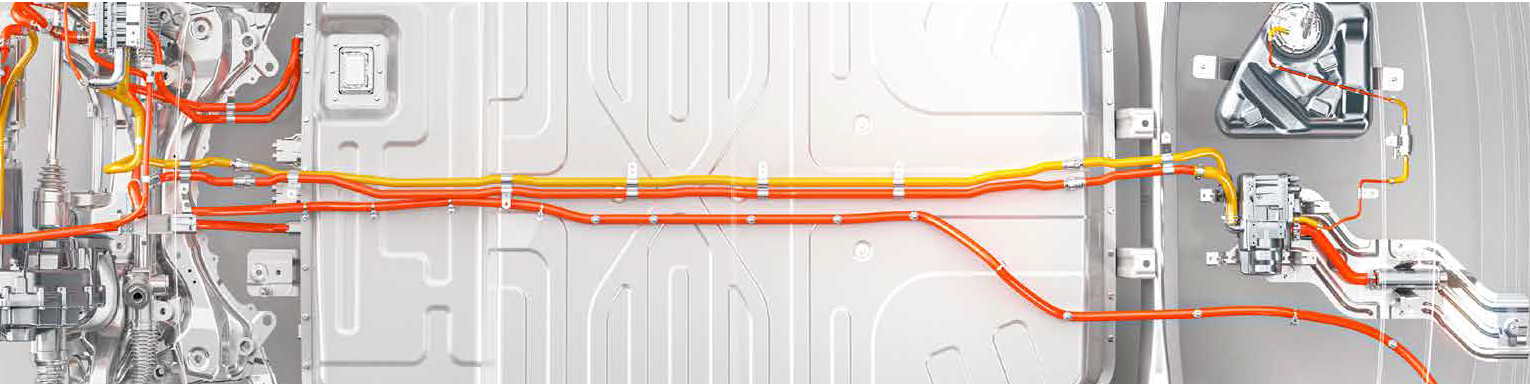

- 4 EV Thermal Solutions

- 5 Seals & Connectors

- 6 EV Cables

- 7 Fuel Cell Sealing

- 8 Two-Component Integrated Sealing Systems

- 9 Front-end Modules

- 10 Sustainable Tire Solutions for Range

Our Silicone Solutions

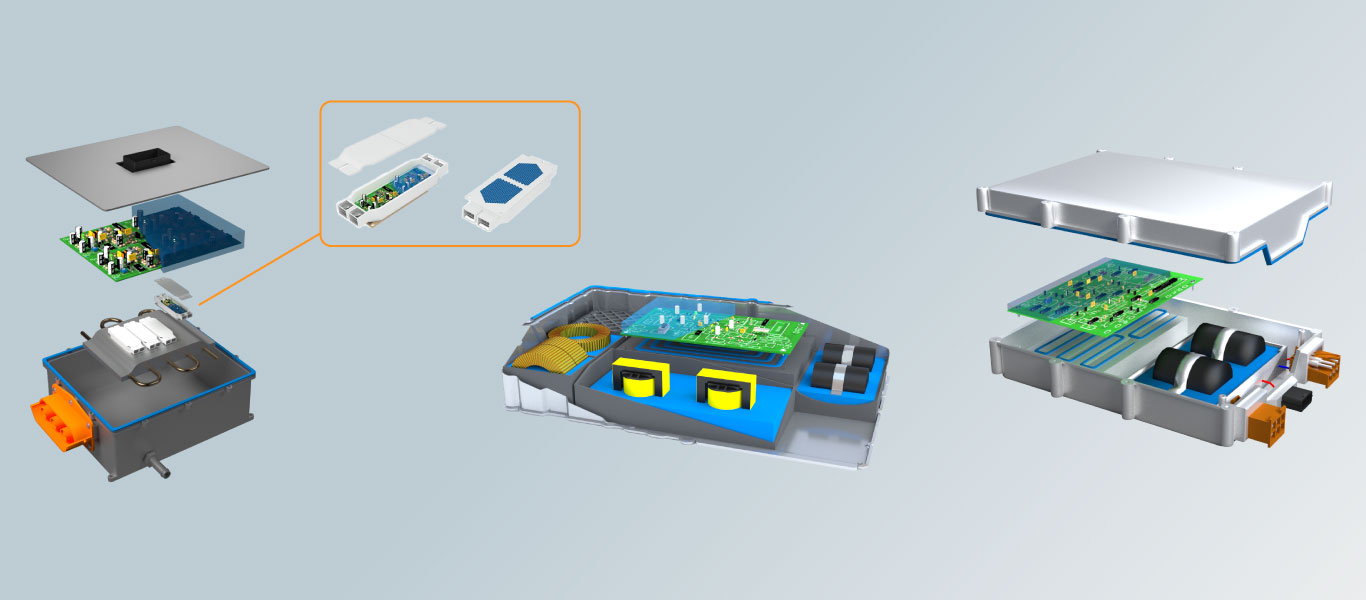

1 Power Electronics ☝

Vehicle power electronics process, control and distribute electric power to other vehicle systems, as well as control the speed and torque of the motor. Momentive silicone solutions offer thermal management, encapsulation/potting, and sealing for power electronics, including inverter systems (and IGBT modules), DC/DC converters, and onboard chargers (pictured left to right, blue areas indicate material applications):

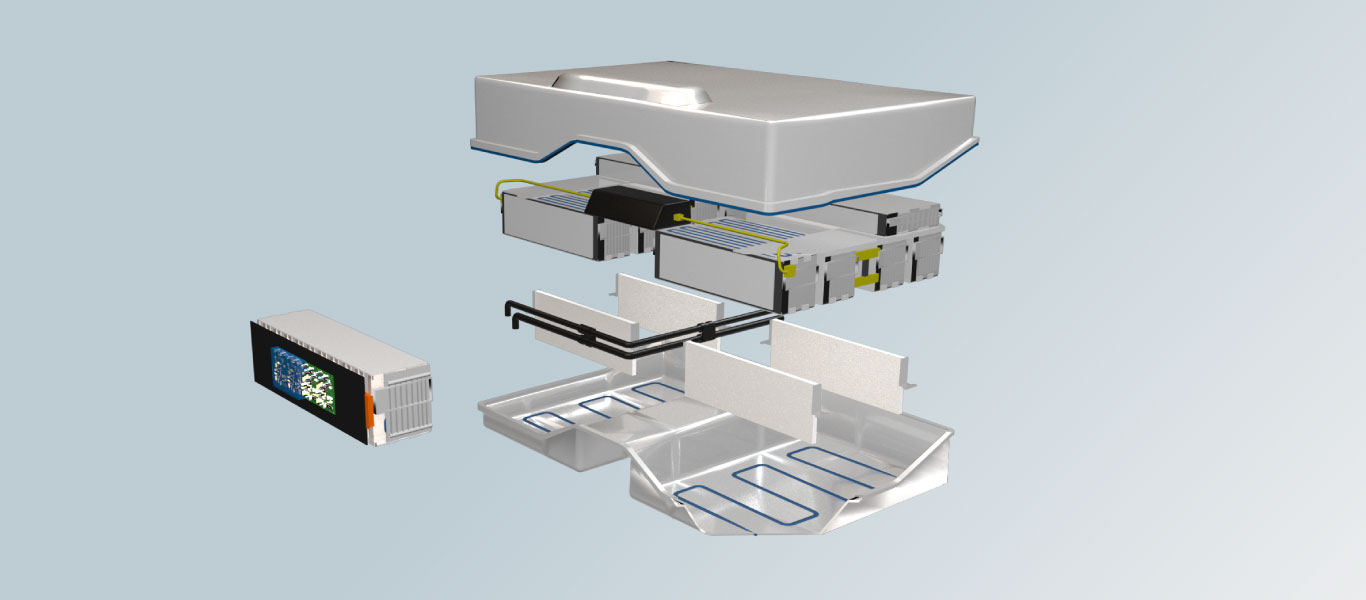

2 High Voltage Battery System ☝

Momentive’s silicone solutions for battery modules include thermal management (thermal gap fillers, adhesives), thermal potting and gel encapsulation, and sealing adhesives, as indicated below:

For battery housing components, Momentive's SFR100 silicone fluid is a non-halogenated flame retardant enables excellent EV fire safety performance without compromising other important properties such as mechanical toughness or non-corrosiveness. For more info, download our marketing bulletin (PDF), or visit our polymer additives website.

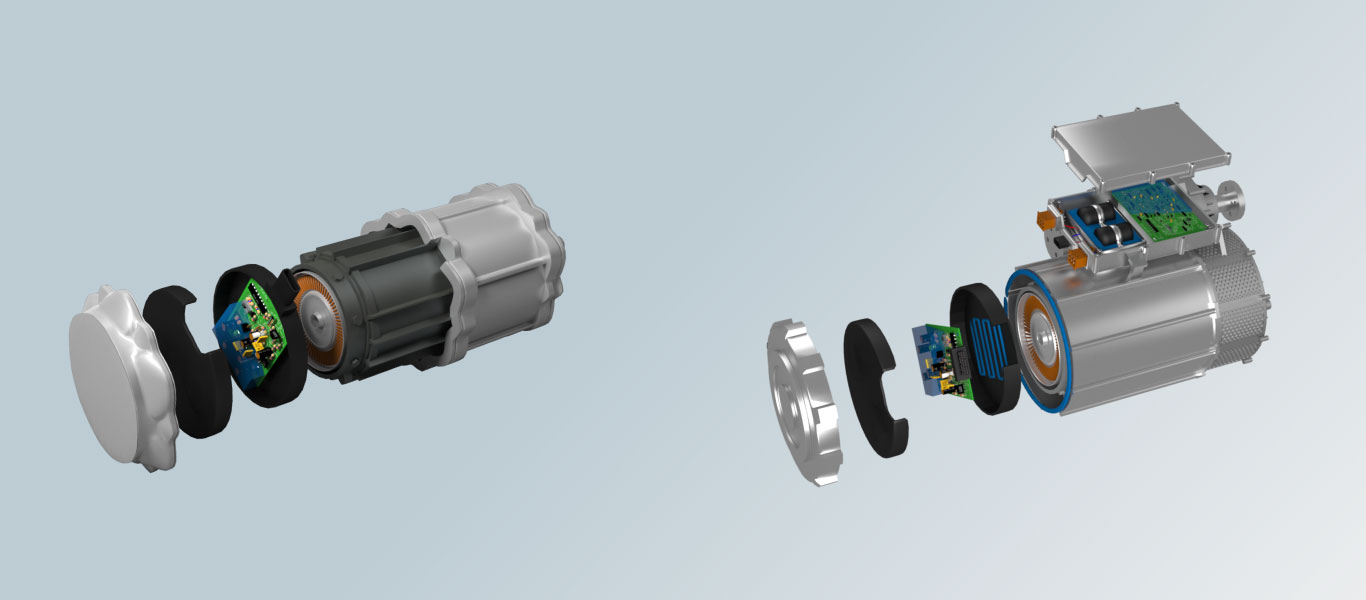

3 Electrified Powertrain ☝

- Silicone applications for the Integrated Drive Motor / Generator include connector potting, encapsulation material, sealing adhesives, and thermal management material. (lower left)

- Silicone applications for the e-axle include encapsulation, connector potting, thermal potting and other thermal management, as well as sealing adhesives. (lower right)

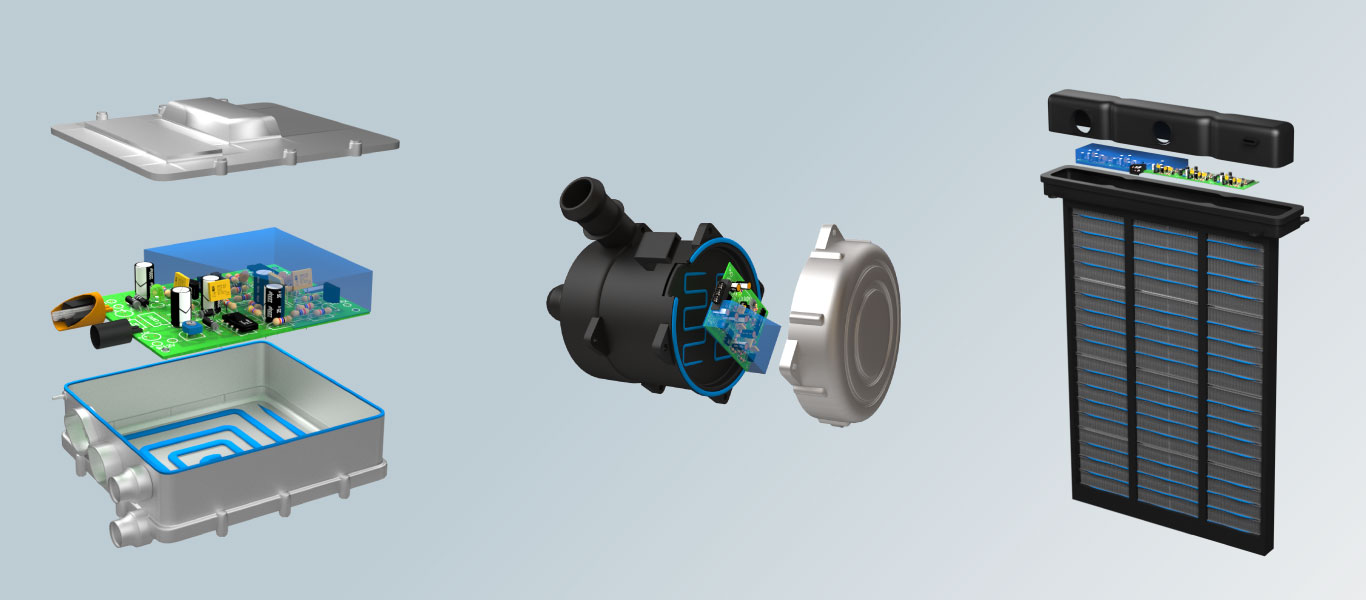

4 EV Thermal Solutions ☝

- Coolant heaters improve battery performance by delivering consistent temperature distribution inside the battery pack and its cells. Silicone applications here include encapsulation, connector potting, thermal management, and sealing adhesives (below, left).

- The electric coolant pump regulates and provides coolant to the cooling system. Silicone applications here include encapsulation and connector potting, thermal management, and sealing adhesive (below, center).

- PTC (Positive Temperature Coefficient) Air Heater heats the vehicle cabin using high-voltage electricity from the battery or hydrogen cell. Silicone applications here include encapsulation, connector potting, thermal management, sealing adhesives, and structural adhesives (below, right).

SilCool™ Thermal Management Series

Momentive's thermal materials offer very low thermal resistance coupled with high reliability. Find out more about: thermal gap fillers, thermal potting and gel encapsulation, thermal management.

Snapsil™ Adhesive Series

Momentive's Snapsil adhesive range offer adhesion to various substrates coupled with outstanding mechanical properties. Find out more: SnapSil Silicone Adhesives & Sealants.

Potting & Encapsulation

Our potting and encapsulation materials offer outstanding protection to electronic components from dust, moisture, fluids and harmful environmental contaminants. Find out more: encapsulation/potting, sealing and bonding adhesives.

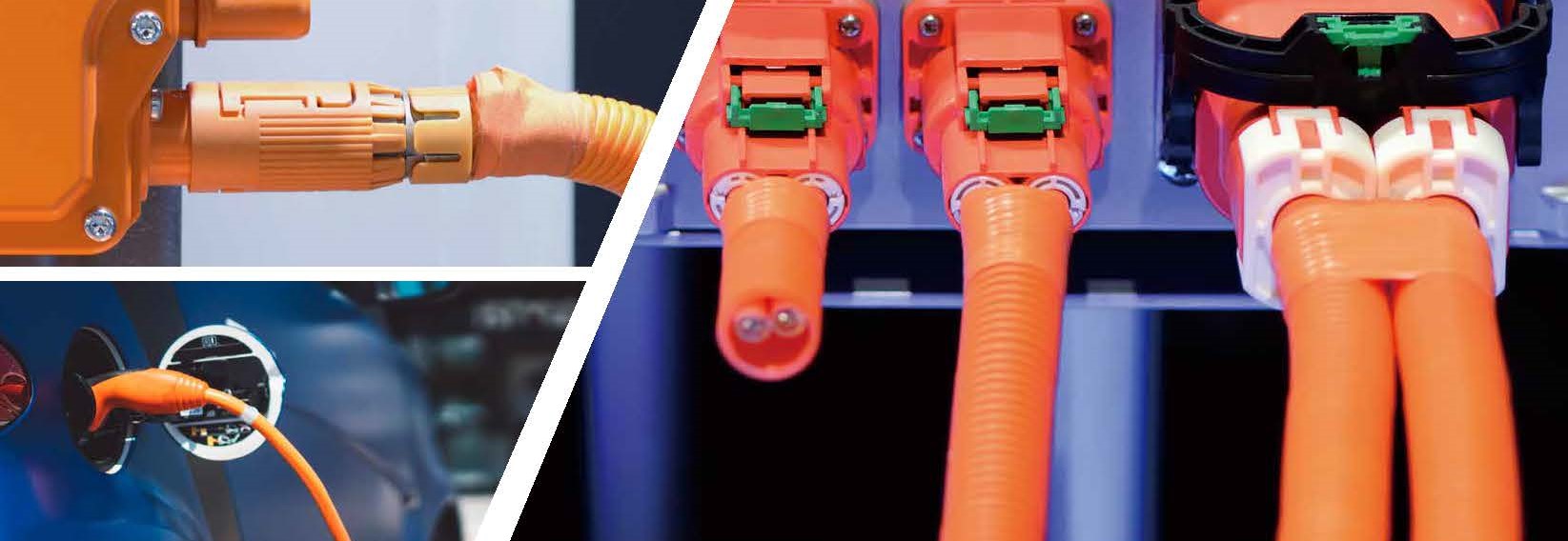

5 Seals and Connectors ☝

Silopren LSR 3000 Series (Self-Lubricating)

Silopren LSR 3366/50 - offers a pairing of high long-term heat-stability with low compression set over extended 1000 hours testing.

Silopren LSR 2700 Series (Self-Bonding)

Silopren LSR 2725/40 - combines primer-less adhesion to many plastic substrates with good lubrication properties.

Silopren LSR 26xx Family

Silopren LSR 2650 - Momentive offers a wide variety of LSR technologies to cover a broad base of application needs across the e-mobility market. The Silopren LSR 2600 Series provides a lower viscosity than the Silopren LSR 2000 Series, improved tear resistance and higher reactivity. Therefore, it provides the ability to reduce the vulcanization temperature while maintaining a equivalent crosslinking and no impact on the physical properties of the vulcanizate.

6 EV Cables ☝

Addisil 2070 - Addisil technology is utilized to meet stringent mechanical, electrical and thermal requirements for e-mobility wire and cable applications. This series is based on an addition cure platinum system that is a particularly attractive solution for high value extrusion applications where compliance, mechanical performance and/or productivity are of critical importance.

7 Fuel Cell Sealing ☝

NL6140DFC - This LSR technology possesses low viscosity to allow decreased injection pressure and, therefore, protection of the bipolar plate substrates during manufacturing/molding. See the brochure below for more details.

8 Two-Component Integrated Sealing Systems ☝

LSR2740 - E-Mobility design engineers now have the ability to leverage two-component hard-soft design systems, and allow the sealing features to be integrated into the engineering thermoplastic part design. This further allows for ease of assemble, and helps ensure critical seal placement and performance.

9 Front-end Modules ☝

In contrast to vehicles of the past, where air flow to the engine was required, with electric vehicles the traditional front grill can be replaced by front end modules made from light-weight plastics, such as polycarbonate. SilFORT hardcoats for automotive offer protection to exterior plastic parts by providing excellent chemical, abrasion and weathering resistance, while maintaining a durable, glossy and easy-to-clean surface. These new design concepts also provide the option of ADAS sensor functionality, headlamp integration, and colorful LED lighting effects, while at the same time protecting decorative design elements on the exterior of electric vehicles.

Other front-end solutions

- Momentive's SFR320 silicone fluid (technical datasheet) improves EV fire safety in non-transparent EV polycarbonate applications such as the front end module, and clear polycarbonate parts such exterior headlamp covers or rear lamp covers, offering an alternative to more corrosive or potentially EHS-compromising choices.

- TSR product family: Our light-diffusing spherical polymethylsilsesquioxane particles can help make undesirable LED 'hot spots' disappear, whereby LED light becomes less irritating to the human eye, while also helping to enable widespread use of energy saving LED lights in EVs.

10 Sustainable Tire Solutions for EV Range, EV Tire Grip and Wear Resistance ☝

Momentive's advanced tire silanes for silica compounds can drive EV innovation further, potentially yielding several improvements in tire performance:

- Range: Reduced tire rolling resistance yielding higher vehicle range

- Greater Grip: Safety, acceleration, handling

- Sustainability: Longer tire life, more miles per charge

NXT™ silane can be considered for use in tread compounds, for improved tire rolling resistance without loss of wet traction. NXT silane enables higher silica loadings, a more stable compound viscosity, improved processability and reduced waste and rework, even in functionalized polymer and high surface area silica compounds. With a partly renewable structure, it can also reduce ethanol emissions during tire production.

NXT™ Z 45 silane is the ultimate performance silane for EV tires, adding improved wear resistance and enabling an ethanol emission-free tire production.