CoatOSil DRI waterborne silicone resin can help reduce water uptake and improve UV resistance in organic waterborne coating compositions. Its chemical structure enables CoatOSil DRI waterborne silicone resin to overcome the difficulties of combining silicone materials with organic waterborne resins.

At this year’s American Coatings Show, we will showcase the benefits of CoatOSil MP 200 silane and CoatOSil T Cure silane oligomer. CoatOSil MP 200 silane principally serves the architectural, paints, resins, acrylic sealants and waterproofing industries. , and is marketed primarily for use in industrial and automotive paints.

CoatOSil MP 200 silane has inherent qualities that can benefit both solvent- borne and waterborne formulations. It promotes adhesion through its ability to react to various organic functionalities, and bonds well to inorganic fillers, pigments and many other inorganic substrates.

CoatOSil* T-Cure silane is a 100% mercapto silane glycolic oligomer used as a crosslinker and adhesion promoter for coating, adhesive and sealant applications. Its primary area of utility is in polyurethane based systems, but it is also able to perform in epoxy, acrylate and hybrid coatings.

The combination of CoatOSil DRI waterborne silicone resin and CoatOSil MP 200 epoxy silane can deliver improved properties in waterborne wood and concrete coating formulations.

With the innovative technology behind it, CoatOSil DRI waterborne silicone resin is an excellent candidate for use in interior and exterior coatings, wood coatings, roof coatings and industrial coatings. CoatOSil DRI waterborne silicone resin is also compatible with many acrylic, styrene acrylic and PUD resin systems.

In the coatings industry, silicone emulsions are known for their durability, water repellency, limited VOC, and resistance to other environmental elements. Momentive’s silicone emulsions can allow formulators to create longer-lasting, protective coatings that maintain aesthetics in interior and exterior architectural applications.

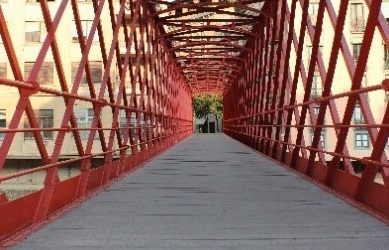

SPUR+* 1050 prepolymer is principally used in the manufacture of one-part, moisture-curing sealants, and as a base resin for medium modulus sealants and adhesives, offering the higher tensile strength that is often required in industrial and transportation applications. With low viscosity and easy application, SPUR + 1050 prepolymer generally adheres well to many surfaces without the aid of a primer.

SPUR+ 3030 prepolymer can enable the formulation of roof coatings that have a wide application window and excellent fully cured properties, including tear, UV and water resistance.

Learn more about our products by downloading our:

Momentive is a global leader in silicones and advanced materials, with a 75- plus year heritage of being first to market with performance applications that support and improve everyday life. Momentive delivers science-based solutions for major industries, by linking its custom technology platforms to allow the creation of unique solutions for customers.

Learn More

Copyright 2020 Momentive Performance Materials Inc. All rights reserved.