NEVSil™

Specialty Elastomers for

New Energy Vehicles

Silicones Enabling New Energy Vehicle Advancements by Momentive

The future of mobility is being redefined with the paradigm shift from traditional internal combustion technology to the steadily growing and continually evolving New Energy Vehicle (NEV) market. As a global leader Momentive is providing solutions to the New Energy vehicle market, we offer a comprehensive portfolio of silicone candidates for a wide variety of NEV applications!

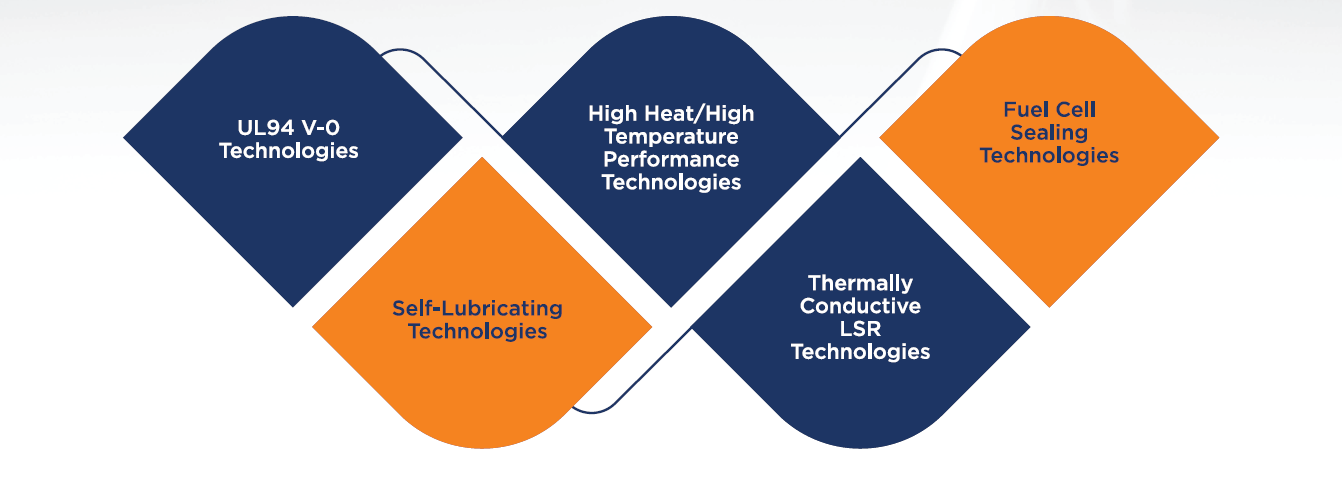

NEVSil™ - Specialty Elastomers for New Energy Vehicles

Momentive's LSR and HCR based material technologies are engineering enablers, providing the ability to meet and exceed demanding application performance requirements NEV's today as well as tomorrow.

Potential Applications

NEVSil™ - Focus on UL94 V0 Applications

Flame retardant Liquid silicone rubber and heat cured silicone rubber technology offerings specifically developed and formulated to provide performance equivalent to UL94 V0.

Momentive's LSR and HCR based material technologies are engineering enablers, providing the ability to meet and exceed the demanding application requirements of today's NEV market.

Key Features and Benefits

- UL94 V0 flammability requirements (1mm thickness)

- Good mechanical properties

- Excellent heat resistance

- Low compression set

- Long pot life at ambient temperature

- UV Curable

- Self-lubricating technology available

NEVSil™ - Focus on Fuel Cell Sealing

NEVSil LSR technology portfolio developed for fuel cell sealing applications includes materials applicable for direct sealing on both the bipolar plate and MEA layer, depending on the particular fuel cell construction.

Key Features and Benefits

- Non post-cure

- Low Viscosity

- High reactivity

- Fast curing

- Low compression set

- Long pot life at ambient temperature

NEV Sealing Application Videos

NEVSil Portfolio Applications

NEVSil Fuel Sealing Application

NEVSil SLFRx0 Series: Self-ubricating UL94 V0 Flame resistant technology

NEVSil SLHRx0 Series: Self-lubricating High temp/Heat performance / Qualified in T5 (1008hr) Applications

Key Features and Benefits

- Self-lubricating

- Offerings meeting UL94 Vo

- Offerings qualified in T5 applications (1008hr)

- Low Viscosity

- High reactivity

- Fast curing

- Low compression set

Potential Applications

Multi-terminal or Mat-seals

Gaskets, seals, o-rings

Connectors

NEVSil™ - Focus on High Heat/High Temperature Performance

Specialized NEVSil HCR technology for use in stringent high temperature environments in which resistance to 300° C is required when catalyzed properly. The NEVSil "HTHR" series offers high temperature silicone rubber compounds in shore A hardness, ranging from 30 to 80 durometer.

Key Features and Benefits

- Outstanding mechanical properties

- Excellent heat resistance

- Low compression set

- Easily blendable to achieve varied durometers

Potential Applications

Boots

Gaskets, seals, o-rings

Battery Sealing

Molded Components

NEVSil™ - Focus on Thermally Conductive LSR

Specialized NEVSil LSR thermally conductive technology

The NEVSil "TC" series offers thermally conductive two-component LSR technology for injection molding. The series has been developed to be utilized in a convenient 1:1 mixing ratio and exhibits a high thermal conductivity.

Key Features and Benefits

- Excellent thermal conductivity

- Good processability

- High reactivity

- High stability and flexibility at low temperatures

- Low compression set

Potential Applications

Heat Transfer Pads

Heat Transfer Pads

Battery Sealing

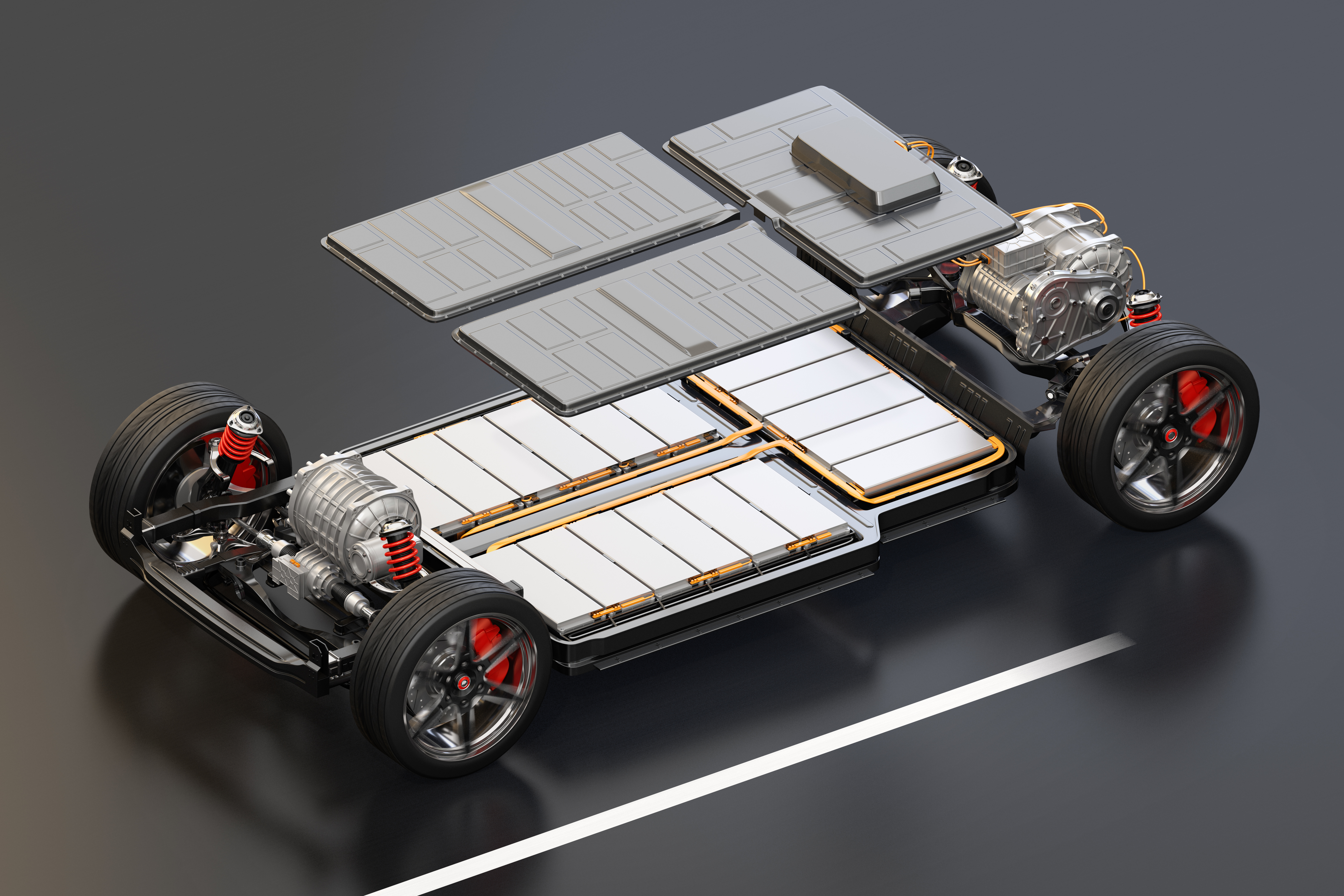

Typical New Energy Vehicle (NEV) Applications

Battery Sealing

- Critical battery sealing applications

- EV battery cushioning

- UL94 V0 / Flammability Requirements

- EV battery Housing Sealing/Gasketing

-

Put-in-place

-

Overmolded W/washer

-

Foldable gasket

Fuel Cell Sealing Applications

- Sealing Bipolar plates (BPP)

- Sealing membrane electrode

- assembly (MEA)

Gaskets, seals, o-rings

- High temperature silicone rubber parts

- O-rings and gaskets

- Molded components

- Critical seals

- Applications requiring superior compression set and long-term heat stability performance

Other Momentive Brands used in Automotive

Silopren™ Liquid Silicone Rubber (LSR)

The Silopren LSR product family is a versatile class of liquid silicone rubbers.Silopren LSR is a two-component addition cured and pumpable silicone elastomer that can be molded and cured with fast cycle times. Key technology families housed under the Silopren tradename include:

- Silopren 3xxx Series: Self-Lubricating LSR technologies for Seals & Connectors

- Silopren LSR 27xx Series: Self-bonding technologies

- Silopren LSR 2xxx and 26xx Series: General Purpose LSR echnologies

- Silopren LSR 25xx Series: Low Viscosity LSR technologies

We are here to help. Get in touch with an expert.

Have a challenge with your current product or application or interested in hearing more about the NEVSil Technology Portfolio?

New Energy Vehicle Trends

Electric Vehicles

Steady Adoption and growth of the EV sector

- Federal EV tax credits and subsidies

- New Attractive EV Models

- High gas/fuel prices

- Environmental benefits / Eco-friendly

- Increased public awareness

- Urbanization

Hydrogen Vehicles

Growing demand for clean power generation

- Green/Renewable energy

- High gas/fuel prices

- Environmental benefits / Eco-friendly

- Increased public awareness

- Stringent carbon emissions requirements Urbanization

Lithium-ion Battery Technology Advancement

Steady advancements in EV battery design

- Advancements in Li-ion battery technology

- Extended ranges >300 miles

- Cost reductions

- Solutions to temperature and heat buildup/dissipation

- Improved safety and reliability

- Rapid Charging

Regulatory

Regulatory

- Tightening emission regulations

- Environmental Impact

- Reduced Co2 Emissions

Innovation

Innovative designs

- 2-Component designs, reducing weight and incorporating sealing functionality

- Innovative material advancements

- Increased high and low temperature performance, increased flammability requirements and resistance

NEVSil Portfolio

Ready to speak to an expert?

* indicates a required field

The use of the "™" symbol designates registered or unregistered trademarks of Momentive Performance Materials Inc. or its affiliated companies. Momentive and the Momentive logo are a registered trademarks of Momentive Performance Materials Inc.